Design for Supply Chain

More than Just Design for Procurement

Get complete alignment between your sourcing strategy and your business strategy with Creation’s Global Materials Sourcing, Design for Supply Chain, and Design for Procurement.

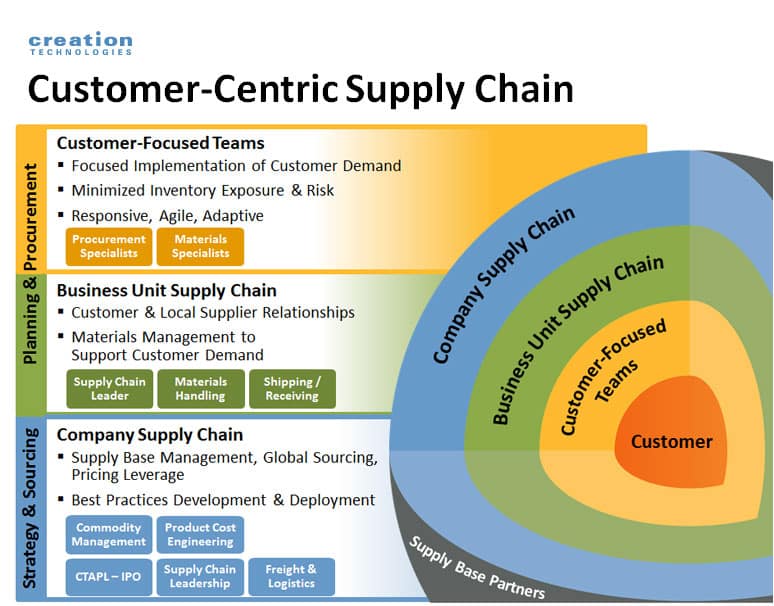

Creation’s customers and collaboration are at the heart of our supply chain expertise and model.

At Creation, we use the insight from our supply base relationships, PLM tools, global market intelligence and custom business systems to provide you with scalable and efficient supply chain solutions.

Learn More about How Design for Supply Chain Can Help You

Creation Technologies: Right-Shore Global Materials Sourcing

Some of the best opportunities for risk mitigation and cost reduction are tied to taking a holistic view of the product lifecycle, in addition to a holistic view of your global production and sourcing strategy.

- Ready-made network of qualified suppliers of off-the-shelf and custom materials that collaborate for your success

- Leverage from Creation’s global spend and history of building respect-driven supply base relationships

- Centralized strategic sourcing and single-instance ERP provide maximum visibility for an optimized total cost from our supply base

- EDI and automated communication with strategic supply base for visibility of constraints

- Ongoing commodity contract review and negotiation

- Supplier Performance measurement and accountability

- Dedicated Procurement and Materials Specialists on your Customer-Focused Team will suggest efficiencies when your requirements change

Expert Procurement through Creation's Global Materials Group

Established in 2006, Creation’s International Purchasing Office (IPO) in Shenzhen is dedicated to sourcing the best materials at the best cost possible.

Creation Technologies Provides You with Expert International Procurement, Quality and Logistics Management:

- Qualified and strategic suppliers for both off-the-shelf and custom materials, such as printed circuit boards (PCBs), metals, cables, plastics and transformers

- Strategic sourcing and quality engineering professionals for high-quality materials and supplier accountability, and customs and logistics documentation

- Team members based in Shenzhen as well as in Vancouver, BC, who are well-versed in social and business cultural differences, and who provide excellent communication across languages and time zones

Creation Technologies Steps Up Efforts to Reduce Supply Chain Risk

The team at Creation Technologies discuss how Creation is mitigating supply chain risks.

Design for Supply Chain, Plus Design for Procurement (DFP)

Prioritizing Design for Procurement (DFP) that includes global sourcing at all stages of the product lifecycle can drive significant advantage in sourcing and procurement.

- Supply chain design and supplier selection for speed, scalability and cost-effectiveness, without sacrificing quality

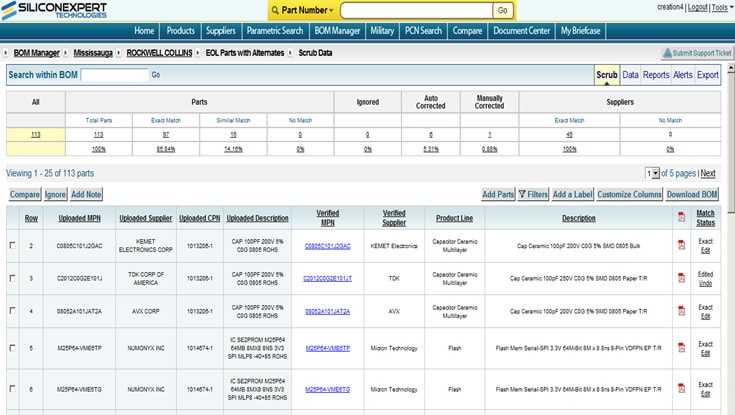

- Design for Procurement (DFP) and Project Lifecycle Management (PLM) tools that mitigate your risk and optimize your supply chain, from NPI through product end-of-life

- Market intelligence: insight into changing costs and lead times

- Cost of Quality of supply base, and recommendations for alternates and AVL improvements

- End-of-Life (EOL) component management and strategic buffers, including counterfeit risk reduction through a very limited number of preferred Independent Distributors

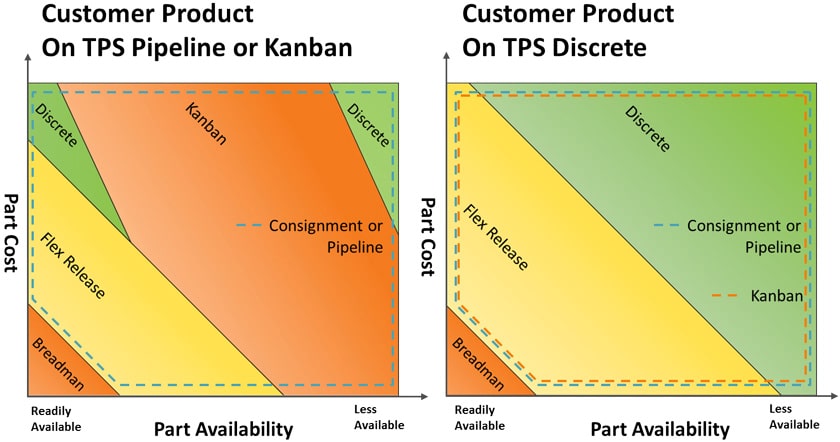

- Lean Supply Chain – Plan for Every Part (PFEP) and Vendor-Managed Inventory (VMI), lean procurement and materials management programs based on raw material characteristics as well as your product delivery strategy

- Inventory, packaging and logistics strategy